Wheel

- 1977.Established Hyundai Precision Co., Ltd. and mass production of small No1 line

- 1986.Completion and mass production of large wheel and small No2 line

- 1998.Completion and mass production of small No3 line

- 2000.Changed the company name of Hyundai Mobis Co., Ltd.

- 2007.Installation and mass production of small wheel TPMS valve assembly line Small wheel ISO/TS 16949 quality management system certification

- 2008.New construction and mass production of painting line

- 2009.Loading / unloading and automatic packing line construction and mass production

- 2010.Achieved production of 100 million steel wheels

- 2015.Take over from MOBIS → Seojin Industrial Ulsan Plant

- 2016.Application of High Edge cover Paint (ED Black) → Improved corrosion

- 2018.IATF 16949 Automotive Quality Management System certification

Function :The wheel is a safety part, which is assembled with the tire to support the vehicle, transmits the friction of the road to the vehicle, and transmits the driving, braking and steering force to the tire so that the vehicle can move.

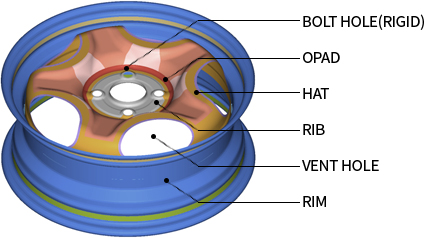

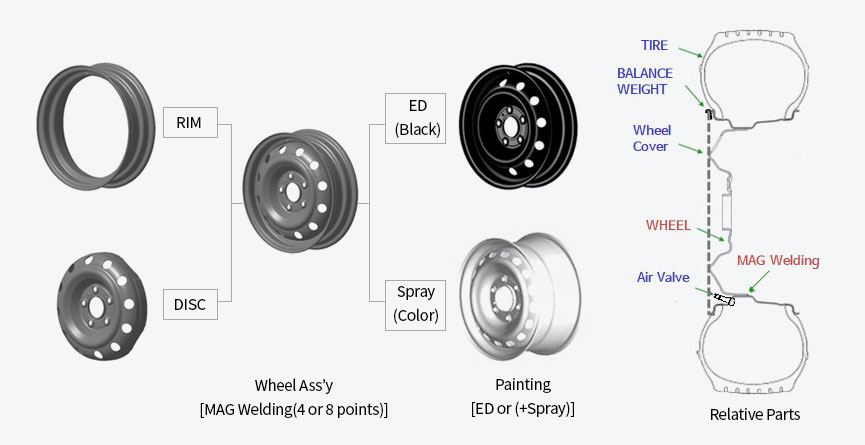

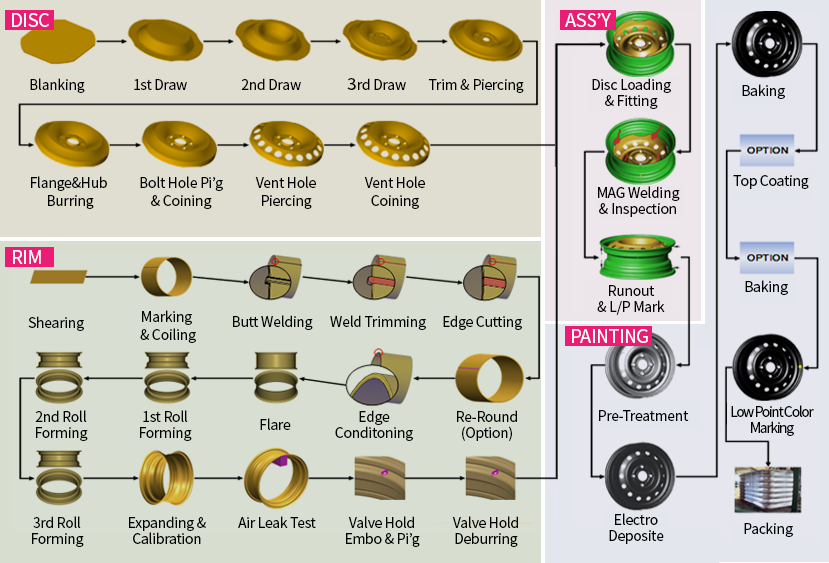

Steel wheel Parts and relative parts

Customer & Model

(2019.06.01)

| Customer | Car Models | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| HMC | Ulsan Plant | Veloster |  |

Accent |  |

Santafe |  |

Tucson |  |

| Avante |  |

i30 |  |

Starex |  |

Porter II |  |

||

| A-san Plant | Sonata |  |

|

||||||

| KMC | Hwasung Plant | K3 |  |

K5 |  |

||||

Product specification and Manufacturing scope

| Customer | Car Model | Items (Common) |

Material & Size | Manufacturing scope | Note | ||||

|---|---|---|---|---|---|---|---|---|---|

| Design | Develop | Producing | QA | ||||||

| HMC | 9 | 14 | Material :Steel Diameter :12~17 Inch Width :3.5~7 inch | O | O | O | O | Design : Techinal Laboratory | |

| KMC | 2 | 2(4) | |||||||

| Sum | 11 | 16(4) | |||||||

[Basic Data]

| Part Name | DISC | RIM | OFFSET | TIRE |

|---|---|---|---|---|

| AX CASE01 | SPFH590 / 5.0t | SPFH590 / 2.3t | 46 mm | 175 / 50 R15 |

| Model View | ||

|---|---|---|

|

|

||

| Load Condition | ||

| Object | AX CASE 01 | |

| Detail | - CFT : 156 kgf·m x 2.0e5 - RFT : 887 kgf x 2.0e6 |

※ Self certification system (CFT Spec.) - 184 kgfㆍm x 6.0e4 - 123 kgfㆍm x 6.0e5 |

[CAE Result]

| Description | VENT | HAT | OPAD | RIB | Judgment | ||

|---|---|---|---|---|---|---|---|

| CFT | ① 20 x 104↑ | Life | 1.51e7 | 3.45e6 | unlimited | 2.12e7 | OK |

| n | 1.55 | 1.35 | - | 1.60 | |||

| ② 6 x 104↑ | Life | 2.29e6 | 6.10e5 | unlimited | 3.12e6 | OK | |

| n | 1.50 | 1.31 | - | 1.55 | |||

| ③ 60 x 104↑ | Life | unlimited | 1.03e8 | unlimited | unlimited | OK | |

| n | - | 1.62 | - | - | |||

| Description | WELD | Judgment | |||||

|---|---|---|---|---|---|---|---|

| RFT | 2 million Cycles ↑ |

Life | 7.38e6 | OK | |||

| n | 1.54 | ||||||

| Load point displacement (mm) |

① 20 x 104 ↑ | ② 6 x 104 ↑ | ③ 60 x 104 ↑ | |||||

|---|---|---|---|---|---|---|---|---|

| 6.224 | 7.341 | 4.907 | ||||||

| Wheel Weight (kg) | 8.82 | |||||||

| Stiffness (kgf/mm) | 1736.53 | |||||||

| Conclusion |

|---|

| Satisfies CFT and RFT target SPEC |

| Desc. | CFT | Desc. | RFT | |||

|---|---|---|---|---|---|---|

| VENT | HAT | OPAD | RIB | |||

| CASE01 (1,736.53kgf/mm) |

|

|

- |

|

CASE01 |

|

| ① 20 x 104 Cycles | 1,510 x 104 (1.55) | 345 x 104 (1.35) | unlimited | 2,120 x 104 (1.60) | MIN 200 x 104 Cycles |

738 x 104 (1.54) |

| ② 6 x 104 Cycles | 229 x 104 (1.50) | 61 x 104 (1.31) | unlimited | 312 x 104 (1.55) | ||

| ③ 60 x 104 Cycles | unlimited | 10,300 x 104 (1.62) | unlimited | unlimited | ||

Road Wheel

| inch | Car Models | Wheel | Customer |

|---|---|---|---|

| 13 inch | Porter II |

|

HMC |

| 14 inch | Accent etc. |

|

HMC |

| 15 inch | Avante etc. |

|

HMC KMC |

| 16 inch | Starex etc. |

|

HMC |

| 17 inch | Tucson |

|

HMC |

Temporary Wheel

| inch | Car Models | Wheel | Customer |

|---|---|---|---|

| 15 inch | Accent etc. |

|

HMC KMC |

| Avante etc. |

|

HMC KMC |

|

| 16 inch | i30 etc. |

|

HMC KMC |

| 17 inch | Santafe etc. |

|

HMC KMC |

| No. | Car Model | Rim Size |

Colour | Mounting Condition (mm) | Customer | Note | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Offset | Hub Hole Dia. |

Bolt Hole | Hyundai Motors |

KIA Motors |

|||||||||||||||

| No. | DIA. | P.C.D | |||||||||||||||||

| 1 | GRAND STAREX / STAREX | 6.5Jx16 | SILVER | 56 | Ø92.3 | 6 | Ø15 | Ø139.7 | ◎ | ||||||||||

| 2 | GRAND STAREX / STAREX | 6.5Jx16 | SILVER | 56 | Ø92.3 | 6 | Ø15 | Ø139.7 | ◎ | ||||||||||

| 3 | TUCSON | 7Jx17 | BLACK | 48 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 4 | SONATA / K5 | 6.5Jx16 | BLACK | 43 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ◎ | |||||||||

| 5 | AVANTE / i30 / K3 | 6Jx15 | BLACK | 46 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ◎ | |||||||||

| 6 | i30 | 6.5Jx16 | BLACK | 48 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 7 | K3 | 6.5Jx16 | BLACK | 50 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 8 | ACCENT | 5.5Jx14 | BLACK | 43 | Ø54 | 4 | Ø15 | Ø100 | ◎ | ||||||||||

| 9 | PORTER II (HR12MY EURO-5) | 6Jx15 | BLACK SILVER |

40 | Ø67 | 5 | Ø17.5 | Ø120 | ◎ | ||||||||||

| 10 | PORTER II (HR12MY EURO-5) | 4Jx13 | BLACK | 94 | Ø112 | 5 | Ø14 | Ø150 | ◎ | Rear | |||||||||

| 11 | PORTER II (HR12MY EURO-5) | 5.5Jx15 | BLACK SILVER |

40 | Ø67 | 5 | Ø17.5 | Ø120 | ◎ | Front | |||||||||

| 12 | K5 / VELOSTER | 4Tx16 | BLACK | 30 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ◎ | Temporary | ||||||||

| 13 | K5 | 4Tx16 | BLACK | 30 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | Temporary | |||||||||

| 14 | K5 / i40 | 4Tx17 | BLACK | 7 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ◎ | Temporary | ||||||||

| 15 | VERACRUZ / SANTAFE | 4Tx17 | BLACK | 30 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | Temporary | |||||||||

| 16 | AVANTE / VELOSTER / i30 / K3 | 4Tx15 | BLACK | 30 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ◎ | Temporary | ||||||||

| No. | Car Model | Rim Size |

Colour | Mounting Condition (mm) | Customer | Note | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Offset | Hub Hole Dia. |

Bolt Hole | Hyundai Motors |

KIA Motors |

|||||||||||||||

| No. | DIA. | P.C.D | |||||||||||||||||

| 1 | PORTER (RR) | 3.5Jx12 | SILVER | 87 | Ø112 | 5 | Ø14 | Ø150 | ◎ | ||||||||||

| 2 | PORTER (FRT) | 5Jx14 | SILVER | 40 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 3 | PORTER (FRT) | 5Jx14 | SILVER | 40 | Ø67 | 5 | Ø17.5 | Ø120 | ◎ | ||||||||||

| 4 | PORTER (RR) | 4Jx13 | BLACK | 95 | Ø134 | 6 | Ø17.5 | Ø170 | ◎ | ||||||||||

| 5 | PORTER II (03MY, RR) | 4Jx12 | SILVER BLACK |

96.5 | Ø112 | 5 | Ø14 | Ø150 | ◎ | ||||||||||

| 6 | LIBERO (FRT) | 5.5Jx14 | BLACK | 40 | Ø67 | 5 | Ø17.5 | Ø120 | ◎ | ||||||||||

| 7 | LIBERO (RR) | 4Jx13 | BLACK | 100 | Ø134 | 6 | Ø17.5 | Ø170 | ◎ | ||||||||||

| 8 | STAREX (97MY) | 5.5Jx14 | SILVER | 40 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 9 | STAREX (00MY) | 5.5Jx14 | SILVER | 40 | Ø67 | 5 | Ø17.5 | Ø120 | ◎ | ||||||||||

| 10 | PRIDE / VERNA | 5.5Jx14 | BLACK | 46 | Ø54 | 4 | Ø15 | Ø100 | ◎ | ◎ | |||||||||

| 11 | AVANTE / i30 | 5.5Jx15 | BLACK | 47 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 12 | AVANTE / i30 | 6Jx15 | BLACK | 46 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 13 | AVANTE | 6.5Jx16 | BLACK | 53 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 14 | i30 | 6.5Jx16 | BLACK | 53 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 15 | VERNA / CLICK | 5Jx14 | BLACK | 46 | Ø54 | 4 | Ø15 | Ø100 | ◎ | ||||||||||

| 16 | VERNA | 5Jx14 | BLACK | 39 | Ø54 | 4 | Ø15 | Ø100 | ◎ | ||||||||||

| 17 | LOCHE | 6.5Jx16 | BLACK | 46 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 18 | SONATA | 6.5Jx16 | BLACK | 46 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 19 | SONATA / K5 | 6.5Jx16 | BLACK | 44 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 20 | i40 | 7Jx16 | BLACK | 40 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 21 | K3 | 6.5Jx16 | BLACK | 51 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 22 | K5 | 6Jx15 | BLACK | 41 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 23 | K5 | 6.5Jx16 | BLACK | 41 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 24 | TUCTON | 6.5Jx17 | BLACK | 48 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 25 | TUCTON | 6.5Jx17 | BLACK | 51 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ||||||||||

| 26 | GRANDEUR | 4Tx16 | BLACK | 46 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | Temporary | |||||||||

| 27 | SONATA | 4Tx16 | BLACK | 30 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | Temporary | |||||||||

| 28 | GENESIS / GRANDEUR / K5 / K7 | 4Tx17 | BLACK | 7 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ◎ | Temporary | ||||||||

| 29 | TUCSON / SPORTAGE R / i30 | 4Tx16 | BLACK | 30 | Ø67 | 5 | Ø15 | Ø114.3 | ◎ | ◎ | Temporary | ||||||||

| 30 | ACCENT | 3.5Jx15 | BLACK | 46 | Ø54 | 4 | Ø15 | Ø100 | ◎ | Temporary | |||||||||

| Line Name | Line no. | Capcity | Shift | |

|---|---|---|---|---|

| Rim & Ass'y Line |

|

2 Lines | 4 million/year |

2 Shift |

|

Paintion Line ED & Spray |

|

1 Lines | 5.64 million/year |

2 Shift |

|

Disc Line (Press) |

|

3 Lines (2 Supplier) |

5.7 million/year |

2 Shift |

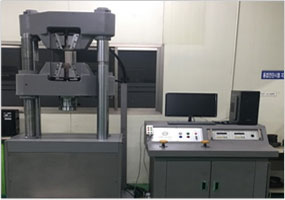

Fatigue Test

Bending Moment Fatigue Test

Bending Moment Fatigue Test

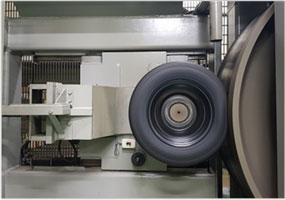

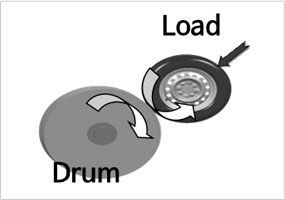

Radial Fatigue Test

Radial Fatigue Test

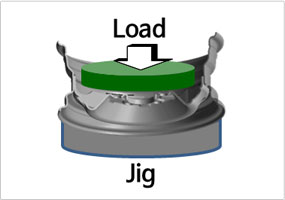

Welding Strength Test

Welding Strength Test

Test Mehod

A) Test condition: Car cornering driving condition

B) Test method

① Wheel fastened to load-bar

② Load-bar rotation

(vehicle driving condition)

③ Apply moment to the load-bar

(cornering condition)

C) Pass condition : No fatigue cracks at less than 200,000 cycles

A) Test condition : Straight running condition of the vehicle

B) Test method

① Drum rotation

② Load on wheels & tires

C) Pass condition : No fatigue cracks at less than 2 million cycles

A) Test purpose : MAG welding strength verification

B) Test specification: ES 52910-01

C) Test method : load on DISC pad surface after fixing RIM

D) Pass condition : No weld crack at less than 33 ton.

Paint Test

Salt Spray Fog Test

Salt Spray Fog Test

Resistance Engine Oil Test

Resistance Engine Oil Test

Resistance Water Test

Resistance Water Test

Test Mehod

A) Purpose: To guarantee the anticorrosion performance of paint film

B) Specification: MS 630-01 (FPO-6H)

C) Method: Cross cut (3 mm) and spray 5% saline water

D) Pass condition : after 720HR, inspection of corrosion and film peeling except 3mm of cutting side

E) Testing of finished products

A) Purpose: To guarantee the anticorrosion performance of paint film

B) Specification: MS 630-01 (FPO-6H)

C) Method: immersing in engine oil

D) Pass condition : after 16HR, should be no discoloration, swell etc.

E) Testing of test piece

A) Purpose: To guarantee the anticorrosion performance of paint film

B) Specification: MS 630-01 (FPO-6H)

C) Method: immersion in water at 40 ℃

D) Pass condition : after 720HR, inspection of corrosion and film peeling except 3mm of cutting side

E) Testing of finished products